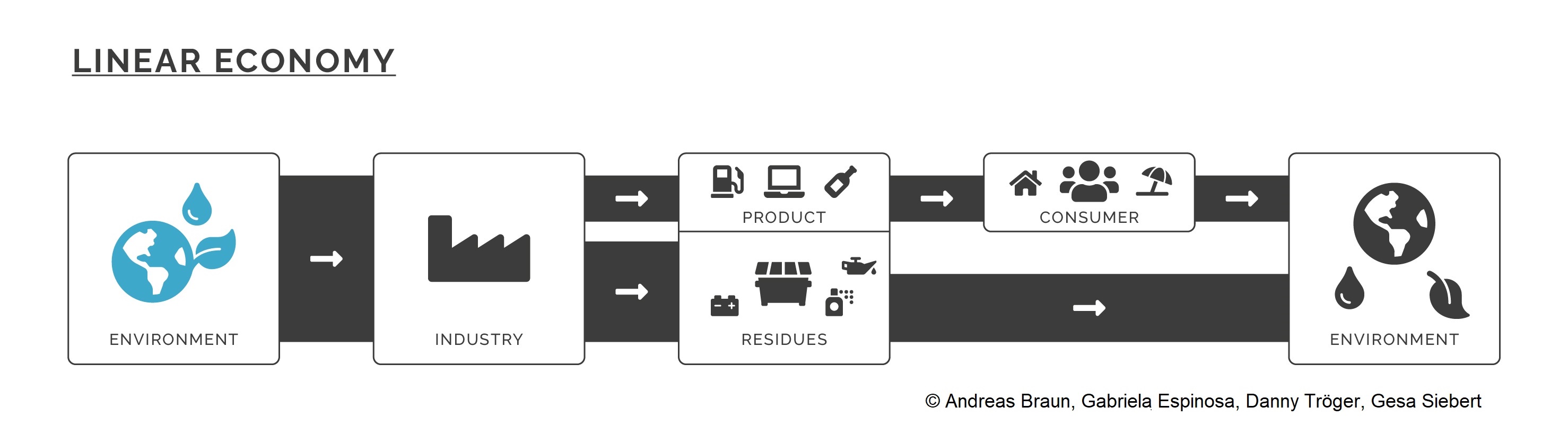

Traditionally, the production style since the industrial revolution has functioned in a linear fashion: raw materials are extracted from nature and transformed into the desired products through manufacturing processes. Then the products are sold, used and eventually thrown away (Fig. 1). The result is a linear economy (also known as “throw-away economy”) which places an enormous burden on the environment as many of our planet’s resources are only available to a limited extent. Furthermore, the natural recovery rate of the natural environment (soil, water, air, ecosystems) is being surpassed by pollution generated directly or indirectly from the production processes or after the use of the products.

Figure 1: Classic production style. Not very sustainable!

To decrease the impacts of the production processes in the environment, the linear production style can (and must!) learn a lot from natural ecosystems. Wolfgang Haber, German biologist and pioneer of landscape ecology in Germany, once described natural ecosystems as “nature’s factories” in which the material flows and organisms are in balance with the environment. In simple terms it works as follows: the plants (producers) produce biomass, which is ingested by other organisms and excreted after digestion. “Decomposer” organisms such as bacteria and fungi transform these excretions so that they can be recycled by producers. This close interaction results in a very efficient use of the resources and material cycles are the results of this interaction.

Natural ecosystems are the inspiration for the emergence of “industrial ecosystems“ and eco-industrial technological developments. Companies are then considered as a species within the same ecosystem, each of them with its own metabolism. They can be linked to the metabolism of other species by means of exchanging energy or material flows. Similar to the description above of a natural ecosystem, in an industrial ecosystem the wastes of one species can become the resources of another species which leads to industrial symbiosis.

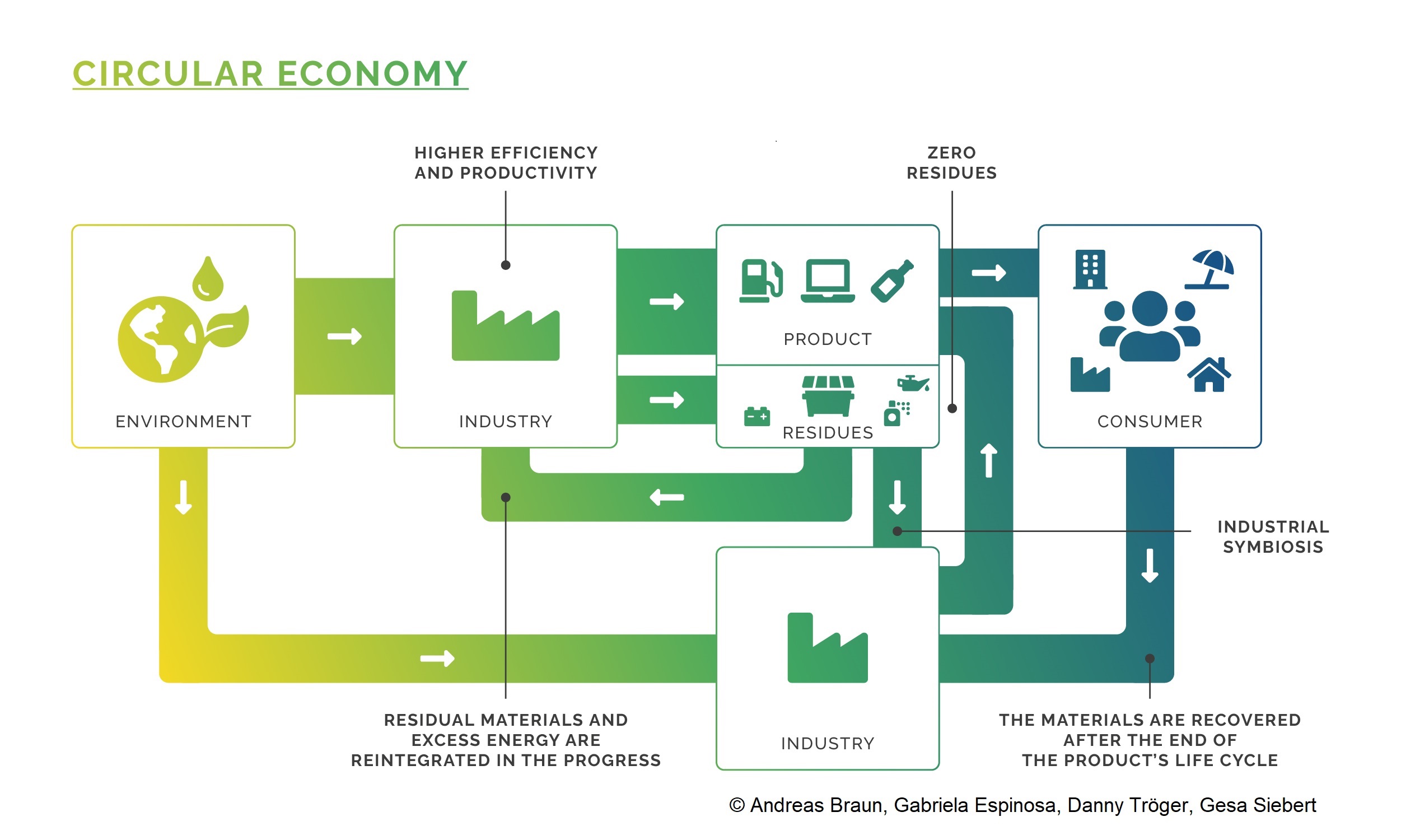

The eco-industrial technological developments aim to contribute to improving the efficiency and productivity of the industrial ecosystems and to get closer to the ideal of a natural ecosystem with zero waste and closed material cycles. This builds the basis of the circular economy (Fig. 2). By considering the entire life cycle of the products from raw material extraction to end disposal (“life cycle assessment”), the transformation and production processes can be designed to increase the productivity and efficiency, thus minimizing the required raw materials and energy consumption along the complete value chain. At the same time, waste amounts can be reduced and the residual materials and excess thermal energy generated in the production processes can be recovered and reused. Furthermore, with an appropriate product design, the valuable components of manufactured goods can be easily separated by type at the end of their life cycle and they can be reintroduced into the material cycles for the same industry or for a totally different production chain.

Figure 2: Ideal production style according to eco-industrial principles. The result is a circular economy that is sustainable.

The institute of Eco-Industrial Development (IECO) aspires to be an internationally visible, German-Chilean institute for the design and implementation of eco-industrial development strategies in Chile and Latin America and aims at shaping the transformation towards a sustainable industry by advising academic, policy and market actors.

IECO works in following Action Fields: Research, Higher Education, and Knowlegde&Technology Transfer. The researchers and partners in IECO collaborate in these action fields through key research lines (Topics). Find out more about the key research lines by visiting the Topics sites.